In This Article

Picture this: you’re cruising effortlessly up that steep hill that used to leave you gasping for breath, feeling the wind in your hair while your electric bike engine does the heavy lifting. That’s the magic of modern electric bike technology! 🚴♂️⚡

✨Was this helpful? Spread the word! 🚀

Whether you’re tired of arriving at work drenched in sweat or dreaming of longer weekend adventures, the right electric bike engine can completely revolutionize your cycling experience. However, with so many options flooding the market in 2025, choosing the perfect motor feels overwhelming. Don’t worry – I’ve spent countless hours researching, testing, and analyzing the best electric bike engine options available today.

From powerful mid-drive systems that climb mountains like they’re molehills to efficient hub motors perfect for daily commuting, this comprehensive guide covers everything you need to know about electric bike engines. Furthermore, we’ll explore real products currently available on Amazon, complete with specifications, pricing, and honest reviews from actual users.

Understanding Electric Bike Engine Technology 🔋

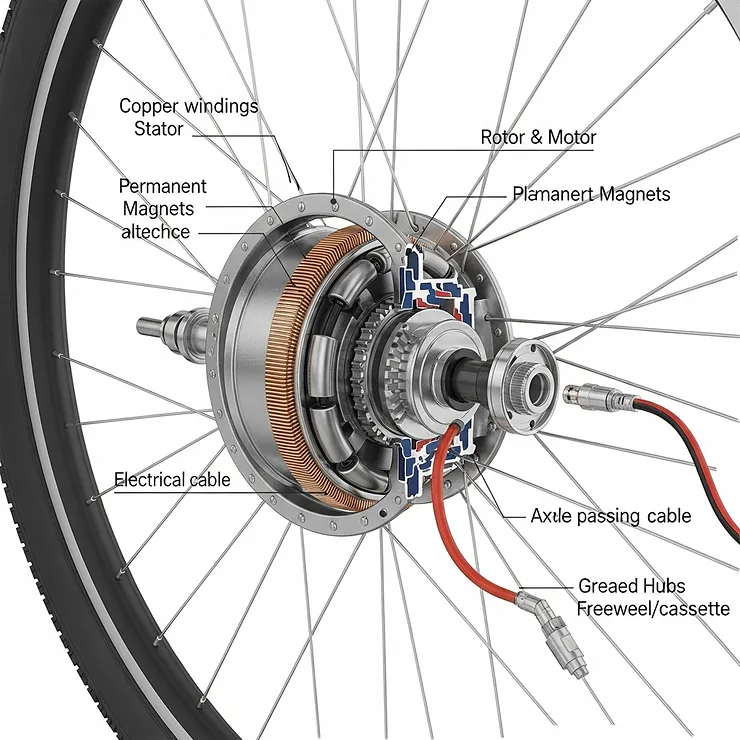

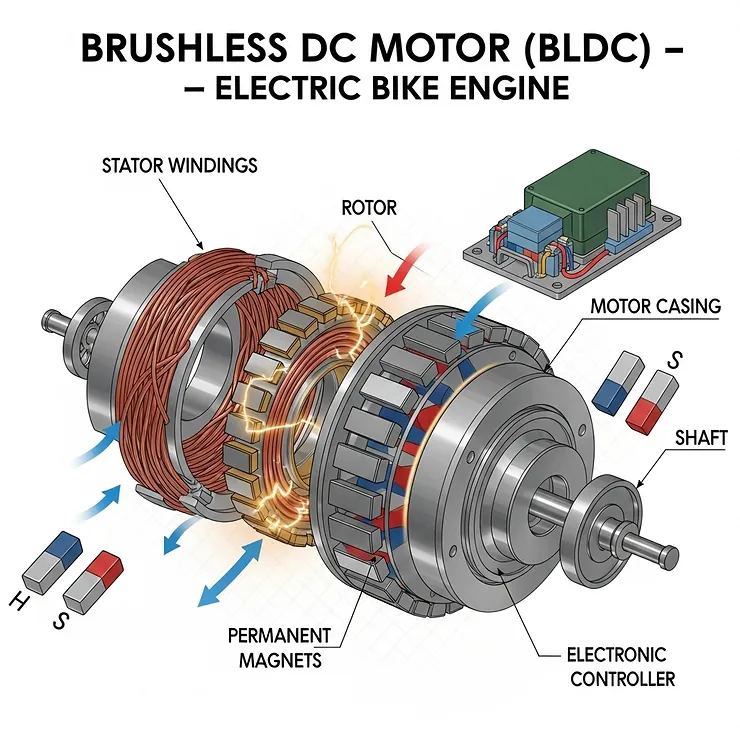

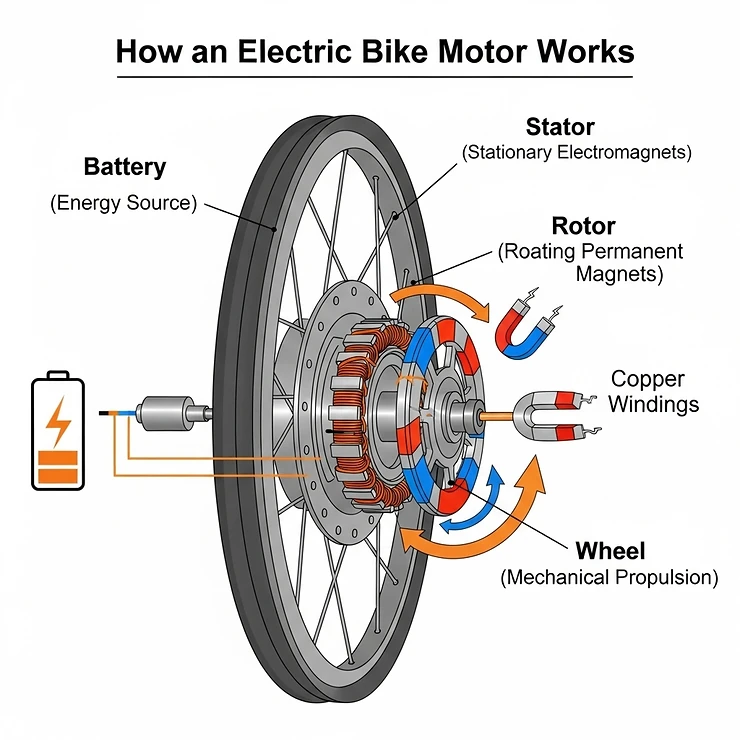

Electric bike engines, also known as e-bike motors, represent the heart of any electric bicycle system. These sophisticated pieces of engineering transform electrical energy from your battery into mechanical power that assists your pedaling. Consequently, understanding how they work helps you make an informed decision.

The basic principle remains surprisingly simple: an electric controller receives input from various sensors (speed, cadence, torque) and delivers appropriate power to the motor. Meanwhile, the motor converts this electrical energy into rotational force that either assists your pedaling directly (mid-drive) or powers your wheels independently (hub motors).

Modern electric bike engines utilize brushless technology, which means they’re incredibly efficient, virtually silent, and require minimal maintenance. Additionally, most systems now include regenerative braking capabilities, allowing you to recover energy while slowing down.

Types of Electric Bike Engines

Mid-Drive Motors 🎯

Mid-drive electric bike engines mount directly to your bike’s bottom bracket, positioning the motor at the bike’s center of gravity. This placement offers superior weight distribution and allows the motor to leverage your bike’s existing gears. Consequently, mid-drive systems excel at climbing hills and provide the most natural riding experience.

Hub Motors 🎯

Hub motors integrate directly into either the front or rear wheel hub. These electric bike engines offer simplicity and ease of installation. Furthermore, they’re typically more affordable than mid-drive options while still providing excellent performance for most riding scenarios.

All-in-One Systems 🎯

Some manufacturers offer complete electric bike engines that include the motor, controller, battery, and display as a integrated package. These systems ensure optimal compatibility and often come with comprehensive warranties.

Top 7 Electric Bike Engine Options in 2025

1. Voilamart Electric Bicycle Conversion Kit 48V 1000W ⚡

The Voilamart Electric Bicycle Conversion Kit stands out as an excellent entry point into electric bike conversions. Priced at $177.99-$189.99 on Amazon, this 48V 1000W rear hub motor delivers impressive performance without breaking the bank.

Key Specifications:

- Power Output: 1000W (switchable to 750W for road-legal compliance)

- Voltage: 48V system

- Maximum Speed: 28mph (45km/h)

- Torque: High-torque brushless motor

- Compatibility: 26″ wheels with 100mm front fork dropout

- Weight Capacity: 330lbs/150kg

Customer reviews consistently praise this electric bike engine for its powerful acceleration and hill-climbing ability. Moreover, the kit includes everything needed for installation, including throttle, controller, and brake levers. However, some users note that the initial spoke tensioning requires attention.

Pros:

✅ Affordable price point

✅ Powerful 1000W motor

✅ Complete kit with all accessories

✅ Dual power mode (750W/1000W)

Cons:

❌ Requires technical installation knowledge

❌ No battery included

❌ May require brake upgrades for safety

2. BAFANG Mid Drive Kit BBS02B/BBS-HD 500W-1000W 🔥

BAFANG represents the gold standard in electric bike engines, and their Mid Drive Kit series demonstrates why. Available in 500W, 750W, and 1000W configurations, these motors offer unmatched versatility and performance.

Key Specifications:

- Power Range: 500W to 1000W options

- Torque: 100-160 N.m depending on model

- Voltage: 48V or 52V systems

- Compatibility: 68-73mm bottom brackets

- Efficiency: >80% motor efficiency

- Display: LCD with multiple data points

The BAFANG electric bike engine system leverages your bike’s existing gears, making it incredibly efficient for climbing and long-distance riding. Additionally, the torque sensor provides natural pedal assist that feels intuitive and responsive.

Professional reviewers consistently rate BAFANG systems among the best available. Furthermore, the company’s ten-year track record and global service network provide peace of mind for long-term ownership.

Pros:

✅ Industry-leading performance

✅ Multiple power options

✅ Excellent build quality

✅ Global service support

Cons:

❌ Higher price point

❌ Complex installation process

❌ Requires compatible bottom bracket

3. AW Electric Bicycle Motor Kit 48V 1000W 26″ 💪

The AW Electric Bicycle Motor Kit offers solid performance at a competitive price point. This 48V 1000W front wheel electric bike engine provides an accessible entry into e-bike conversion while maintaining reasonable quality standards.

Key Specifications:

- Power: 48V 1000W brushless motor

- Wheel Size: 26″ x 1.75″ compatibility

- Controller: Dual mode with intelligent features

- Speed: Up to 28 MPH capability

- Installation: Front or rear wheel options

- Throttle: Both twist and thumb throttle included

Customer feedback reveals mixed experiences with this electric bike engine. While many appreciate the affordability and complete kit contents, some report controller reliability issues. However, the majority of users find adequate performance for casual riding and commuting.

Pros:

✅ Complete conversion kit

✅ Dual throttle options

✅ Competitive pricing

✅ Front or rear wheel options

Cons:

❌ Quality control inconsistencies

❌ Limited customer support

❌ Installation instructions could be clearer

4. BAFANG Rear Hub Motor Kit 48V 500W/750W 🎯

BAFANG’s Rear Hub Motor Kit combines the company’s renowned quality with the simplicity of hub motor installation. Available in both 500W and 750W configurations, this electric bike engine strikes an excellent balance between performance and practicality.

Key Specifications:

- Power Options: 500W or 750W

- Torque: 80 N.m maximum

- Speed: Up to 38-40 KM/H

- Efficiency: ≥80% motor efficiency

- Compatibility: 135-142mm rear dropouts

- Brake Compatibility: Disc or V-brake systems

This electric bike engine system includes comprehensive accessories and detailed installation guides. Moreover, BAFANG’s global service network ensures support availability worldwide. The motor’s IPX5 waterproof rating provides confidence for all-weather riding.

Pros:

✅ BAFANG quality and reliability

✅ Comprehensive accessory kit

✅ Global service network

✅ Weather-resistant design

Cons:

❌ Higher price than generic options

❌ Limited to hub motor limitations

❌ Battery sold separately

5. ENGWE Engine Pro 1000W/1200W Adult Folding E-Bike 🚀

The ENGWE Engine Pro represents a complete electric bike solution rather than just a conversion kit. This folding electric bike engine system delivers impressive performance in a portable package.

Key Specifications:

- Motor Power: 1000W (upgradeable to 1200W)

- Battery: 48V 16Ah or 52V 16Ah options

- Range: 31 miles electric / 93 miles assist mode

- Folding Design: 40×21×33 inches when folded

- Weight: 68.34lbs with 330.7lbs load capacity

- Suspension: Full dual suspension system

Customer reviews highlight the Engine Pro’s exceptional range and powerful motor performance. Additionally, the folding design makes it practical for urban commuters with limited storage space. The integrated LCD display provides comprehensive ride data and USB charging capability.

Pros:

✅ Complete e-bike solution

✅ Impressive range capabilities

✅ Folding design for portability

✅ Full suspension system

Cons:

❌ Heavy weight limits portability

❌ Higher price point

❌ Assembly required

6. Bimotal Elevate 750W Motor Kit 🌟

The Bimotal Elevate represents cutting-edge electric bike engine technology with its unique quick-release design. Priced at $2,995, this premium system allows instant conversion between electric and analog riding.

Key Specifications:

- Power: 750W with 70Nm peak torque

- Battery: 300Wh removable pack

- Weight: 8.8 lbs total system weight

- Speed: 20 mph (Class 2 compliant)

- Range: 10-15 miles typical use

- Compatibility: Disc brake bikes only

This innovative electric bike engine mounts to your bike’s disc brake rotor, requiring no permanent modifications. Furthermore, the system can be shared between multiple bikes, maximizing value for multi-bike households.

Early adopters praise the Elevate’s seamless integration and natural feel. However, the premium pricing limits its accessibility for budget-conscious consumers.

Pros:

✅ Revolutionary quick-release design

✅ No permanent bike modifications

✅ Shareable between bikes

✅ Premium engineering quality

Cons:

❌ Very high price point

❌ Limited range

❌ Requires specific brake compatibility

7. BAFANG Ebike Conversion Kit 48V 500W/750W Rear Hub Motor 🔧

This BAFANG Ebike Conversion Kit rounds out our selection with another excellent hub motor option. The 48V system with 500W or 750W power options provides flexibility for different riding needs and legal requirements.

Key Specifications:

- Power: 500W or 750W options

- Torque: 80 N.m maximum output

- Speed: Up to 45 KM/H capability

- Waterproof: IPX5 rating

- Noise Level: <55dB operation

- PAS System: 4 distinct riding modes

This electric bike engine system emphasizes user-friendly installation with comprehensive documentation and video guides. Additionally, the intelligent controller provides smooth power delivery and customizable performance settings.

Pros:

✅ Multiple power options

✅ Quiet operation

✅ Weather resistant

✅ User-friendly installation

Cons:

❌ Hub motor limitations

❌ Battery purchased separately

❌ Installation still requires mechanical skills

Electric Bike Engine Performance Comparison Table

| Motor | Power | Torque | Price Range | Best For | Installation |

|---|---|---|---|---|---|

| Voilamart 1000W | 1000W/750W | High | $177-189 | Budget builds | Moderate |

| BAFANG Mid-Drive | 500-1000W | 100-160 Nm | $300-600 | Performance | Complex |

| AW 1000W Kit | 1000W | Medium | $200-300 | Basic conversion | Easy |

| BAFANG Hub 750W | 500-750W | 80 Nm | $250-400 | Reliable commuting | Moderate |

| ENGWE Complete | 1000W | High | $1500-2000 | Ready-to-ride | Pre-built |

| Bimotal Elevate | 750W | 70 Nm | $2995 | Premium experience | Unique |

| BAFANG Hub Kit | 500-750W | 80 Nm | $300-500 | Versatile use | Moderate |

💬 Just one click – help others make better buying decisions too!😊

Don’t Miss These Exclusive Motor Deals! 🎯

→Ready to transform your bike into an electric powerhouse? Click on any highlighted electric bike engine to check current pricing and availability. These motors will revolutionize your cycling experience! 🚴♂️⚡

Industry-Specific Applications

Electric bike engines serve diverse industries and applications beyond recreational cycling. Understanding these specialized uses helps illustrate the technology’s versatility and potential.

Commercial Delivery Services 📦

Delivery companies increasingly rely on electric bike engines to reduce operational costs and environmental impact. Companies like UberEats, DoorDash, and local courier services deploy e-bikes equipped with powerful mid-drive or hub motors. These electric bike engine systems typically feature 500W-750W motors paired with large capacity batteries for all-day operation.

Professional delivery riders report significant cost savings compared to motorcycles or cars. Moreover, electric bike engines provide consistent performance regardless of rider fitness level, ensuring reliable delivery times. The motors’ ability to handle heavy cargo loads while maintaining speed makes them ideal for urban delivery scenarios.

Law Enforcement and Security 🚔

Police departments worldwide adopt electric bike engines for patrol duties. These specialized applications require motors capable of quick acceleration, sustained speeds, and reliable performance under stress. Typically, law enforcement e-bikes feature powerful mid-drive systems ranging from 750W to 1000W.

The silent operation of modern electric bike engines provides tactical advantages for patrol officers. Additionally, the extended range capabilities allow officers to cover larger patrol areas without fatigue. Many departments report improved community engagement when officers patrol on e-bikes rather than in vehicles.

Healthcare and Medical Applications 🏥

Healthcare workers utilize electric bike engines for various applications, from hospital campus transportation to mobile medical services. The motors enable medical personnel to carry heavy equipment while maintaining mobility and speed.

In developing countries, electric bike engines power mobile clinics and medical supply delivery systems. These applications demonstrate the technology’s potential for improving healthcare access in underserved communities.

Tourism and Recreation Industry 🌄

Tourist destinations increasingly offer electric bike engine-powered rental fleets. These systems allow visitors of varying fitness levels to explore mountainous terrain, coastal paths, and urban areas. Tour operators report higher customer satisfaction and expanded demographic reach with e-bike offerings.

The electric bike engine technology enables longer tour routes and more challenging terrain accessibility. Furthermore, guided e-bike tours can accommodate mixed-ability groups, ensuring everyone enjoys the experience regardless of fitness level.

Agricultural and Rural Applications 🚜

Farmers and rural workers utilize electric bike engines for property management, livestock monitoring, and equipment transportation. The motors provide quiet operation that doesn’t disturb animals while offering sufficient power for carrying tools and supplies across large properties.

Electric bike engines prove particularly valuable for organic farms and environmentally conscious agricultural operations. The zero-emission operation aligns with sustainable farming practices while providing practical transportation solutions.

Advanced Technical Analysis

Modern electric bike engine technology incorporates sophisticated engineering principles that optimize performance, efficiency, and user experience. Understanding these technical aspects helps users make informed decisions and maximize their investment.

Motor Construction and Engineering 🔧

Contemporary electric bike engines utilize permanent magnet synchronous motor (PMSM) technology for optimal efficiency and power density. These motors feature rare earth magnets, typically neodymium-iron-boron (NdFeB), which provide exceptional magnetic field strength in compact packages.

The stator windings use high-grade copper with advanced insulation materials rated for continuous operation at elevated temperatures. This construction ensures longevity and consistent performance even under demanding conditions. Additionally, modern electric bike engines incorporate advanced cooling systems, including finned housings and thermal management materials.

Bearing systems represent another critical component in electric bike engine design. High-quality motors utilize sealed cartridge bearings with specialized lubricants designed for extended operation intervals. These bearings reduce friction losses and extend motor life significantly compared to basic bushing systems.

Electronic Control Systems ⚡

The electronic speed controller (ESC) serves as the brain of any electric bike engine system. Modern controllers utilize field-oriented control (FOC) algorithms that provide smooth power delivery and maximum efficiency across the entire operating range.

Advanced controllers incorporate multiple sensor inputs including hall effect sensors, encoders, and torque sensors. This multi-sensor approach enables precise motor control and natural pedal assist characteristics. Furthermore, modern electric bike engine controllers feature programmable parameters that allow customization for specific applications and rider preferences.

Regenerative braking capability represents another significant advancement in electric bike engine technology. During deceleration, the motor operates as a generator, converting kinetic energy back into electrical energy stored in the battery. This feature extends range while providing additional braking force.

Battery Integration and Management 🔋

Electric bike engine performance depends heavily on battery system design and management. Modern lithium-ion batteries utilize advanced cell chemistry, typically lithium nickel manganese cobalt oxide (NMC) or lithium iron phosphate (LiFePO4), optimized for cycling applications.

Battery management systems (BMS) monitor individual cell voltages, temperatures, and current flow to ensure safe operation and maximize battery life. Advanced BMS implementations include cell balancing algorithms that maintain uniform charge levels across all cells, preventing premature capacity loss.

The integration between electric bike engine controllers and battery management systems enables sophisticated power management strategies. These systems can adjust motor power output based on battery state of charge, temperature, and available capacity, ensuring optimal performance throughout the entire ride.

Thermal Management and Cooling 🌡️

Heat generation represents a significant challenge for electric bike engine design. High-power motors generate substantial heat during operation, particularly during hill climbing or sustained high-speed riding. Effective thermal management ensures consistent performance and prevents component damage.

Modern electric bike engines incorporate multiple cooling strategies including passive air cooling, thermal conduction paths, and active cooling systems. The motor housing design includes cooling fins and optimized airflow channels that promote heat dissipation during operation.

Some premium electric bike engine systems feature active cooling with small fans or liquid cooling systems. These advanced cooling solutions enable sustained high-power operation without thermal derating, maintaining peak performance even during demanding riding conditions.

Comprehensive Setup and Usage Guide

Installing and configuring an electric bike engine requires careful attention to mechanical, electrical, and safety considerations. This comprehensive guide provides step-by-step procedures for successful installation and optimal performance.

Pre-Installation Assessment 🔍

Before beginning any electric bike engine installation, conduct a thorough assessment of your bicycle’s compatibility and condition. Examine the frame material, construction quality, and existing component conditions. Aluminum and steel frames typically provide adequate strength for electric bike engine installation, while carbon fiber frames may require special considerations.

Measure critical dimensions including bottom bracket width (for mid-drive systems), dropout spacing (for hub motors), and frame clearances. These measurements ensure proper fit and prevent interference issues during installation. Additionally, assess the existing brake system capacity, as electric bike engines require upgraded stopping power for safety.

Document your bike’s current configuration with photographs and measurements. This documentation proves valuable during installation and helps troubleshoot any issues that arise. Furthermore, create a parts inventory to ensure all necessary components are available before beginning work.

Tool Requirements and Preparation 🛠️

Electric bike engine installation requires specialized tools beyond basic bicycle maintenance equipment. Essential tools include torque wrenches (covering 5-50 Nm range), cable cutters, soldering equipment, and electrical testing tools. Additionally, specific tools may be required for bottom bracket removal or wheel building depending on your chosen motor type.

Prepare a clean, well-lit workspace with adequate room for bicycle positioning and parts organization. Ensure electrical safety by having proper grounding equipment and avoiding work in damp conditions. Furthermore, gather safety equipment including safety glasses, work gloves, and first aid supplies.

Review all installation documentation before beginning work. Most reputable electric bike engine manufacturers provide detailed installation guides, wiring diagrams, and troubleshooting procedures. Familiarize yourself with these materials to avoid common installation mistakes.

Mid-Drive Installation Procedure 🔧

Mid-drive electric bike engine installation begins with bottom bracket removal. Use appropriate tools to remove the existing bottom bracket, taking care to note thread direction and any special requirements. Clean the bottom bracket shell thoroughly and inspect for damage or wear.

Install the motor mounting hardware according to manufacturer specifications, ensuring proper torque values and thread locker application where specified. Position the electric bike engine carefully, aligning all mounting points and ensuring adequate clearance for all moving parts.

Route electrical cables carefully, avoiding sharp edges, heat sources, and moving components. Use appropriate cable management accessories to secure wiring and prevent damage during operation. Furthermore, ensure all electrical connections are clean, secure, and properly insulated.

Hub Motor Installation Process ⚙️

Hub motor electric bike engine installation typically involves wheel building or wheel replacement. If replacing an existing wheel, carefully transfer components including tire, tube, rim tape, and cassette or freewheel to the new motorized wheel.

For spoke replacement installations, remove the existing rim and transfer spokes to the motorized hub. This process requires wheel building experience and proper spoke tensioning to ensure safety and performance. Consider professional wheel building services if you lack experience with this procedure.

Install the completed motor wheel in the frame, ensuring proper alignment and secure fastening. Connect all electrical cables according to the wiring diagram, paying special attention to connector orientation and secure engagement. Test all connections before final assembly.

Controller and Display Configuration 📱

Modern electric bike engine systems feature programmable controllers that require configuration for optimal performance. Connect the display unit and access the configuration menu according to manufacturer instructions. Key parameters include wheel size, motor power limits, pedal assist levels, and safety cutoff settings.

Configure pedal assist sensitivity to match your riding preferences and local regulations. Most systems offer multiple assist levels with adjustable power output and response characteristics. Additionally, set speed limits and power restrictions to comply with local e-bike regulations.

Test all functions systematically including throttle response, pedal assist operation, and brake cutoff switches. Verify that the display shows accurate speed, battery level, and other critical information. Furthermore, ensure all safety systems function correctly before riding.

Initial Testing and Calibration 🧪

Conduct initial testing in a safe, controlled environment away from traffic and obstacles. Begin with low power settings and gradually increase power output while monitoring system behavior. Pay attention to unusual noises, vibrations, or irregular behavior that might indicate installation issues.

Perform brake testing at low speeds to ensure adequate stopping power with the added weight and speed of the electric bike engine system. Upgrade brake pads or brake systems if necessary to maintain safety margins. Additionally, test all electrical systems including lights, displays, and charging functions.

Document baseline performance including range testing under various conditions. This information helps establish normal operating parameters and identify potential issues during ongoing use. Furthermore, schedule follow-up inspections to monitor component wear and adjustment requirements.

Maintenance and Longevity

Proper maintenance ensures maximum lifespan and reliable performance from your electric bike engine investment. Regular maintenance schedules prevent costly repairs and maintain optimal efficiency throughout the motor’s operational life.

Daily Maintenance Procedures 📅

Daily electric bike engine maintenance focuses on basic cleanliness and visual inspections. Clean exterior surfaces with a damp cloth, avoiding direct water exposure to electrical components. Inspect all visible wiring for damage, wear, or loose connections that might affect performance or safety.

Check tire pressure and wheel alignment, as these factors significantly impact motor efficiency and battery range. Low tire pressure increases rolling resistance, forcing the electric bike engine to work harder and reducing overall efficiency. Furthermore, misaligned wheels create additional drag and uneven wear patterns.

Verify proper operation of all control functions including throttle response, pedal assist engagement, and brake cutoff switches. Test the display system for accurate readings and proper function of all indicators. Additionally, ensure the battery is properly secured and charging connections are clean and tight.

Weekly Maintenance Schedule 🗓️

Weekly maintenance expands to include more detailed inspections and preventive care procedures. Remove the battery and inspect all electrical connections for corrosion, looseness, or damage. Clean connection points with appropriate electrical contact cleaner and apply dielectric grease where specified.

Inspect the electric bike engine mounting points for security and proper torque specifications. Mid-drive systems require particular attention to bottom bracket tightness and chain line alignment. Hub motor systems need wheel security and spoke tension verification.

Lubricate the chain and drivetrain components according to manufacturer recommendations. Clean chain and sprockets remove debris that increases wear and reduces efficiency. Additionally, inspect brake pads for wear and adjust brake cable tension as needed.

Monthly Maintenance Tasks 📊

Monthly maintenance includes comprehensive system checks and preventive replacements. Perform detailed electrical system testing including voltage measurements, current draw analysis, and insulation resistance testing. These tests identify developing problems before they cause system failures.

Inspect all mechanical fasteners for proper torque and apply thread locker where specified. Pay particular attention to motor mounting bolts, wheel nuts, and brake hardware. Loose fasteners can cause vibration, premature wear, or safety hazards.

Clean and inspect the electric bike engine cooling system including air passages and cooling fins. Remove debris buildup that restricts airflow and reduces cooling efficiency. Additionally, check for proper operation of any cooling fans or active cooling systems.

Quarterly Service Intervals 🔧

Quarterly maintenance includes major service items and component replacements. Replace brake pads if wear indicators show needed replacement, and bleed hydraulic brake systems according to manufacturer schedules. Electric bike engines require enhanced braking capability due to increased speeds and weights.

Perform comprehensive electrical system testing including controller calibration and sensor alignment. Many systems benefit from periodic recalibration to maintain optimal performance as components age and wear. Furthermore, update controller firmware if manufacturer updates are available.

Inspect and service wheel bearings, particularly for hub motor systems that experience additional loads from motor operation. Replace bearings if roughness, play, or noise indicates wear. Additionally, check spoke tension and wheel trueness, adjusting as necessary for safety and performance.

Annual Service Requirements 🗓️

Annual maintenance includes major component inspections and replacements that ensure continued safe operation. Remove and disassemble the electric bike engine for internal inspection and cleaning. This service identifies internal wear patterns and prevents catastrophic failures.

Replace all consumable electrical components including brake sensors, throttle assemblies, and display units if manufacturers recommend periodic replacement. These components experience continuous use and may degrade over time, affecting safety and performance.

Conduct comprehensive range testing and performance analysis to establish baseline measurements for the coming year. Compare current performance to historical data to identify degradation trends and schedule appropriate maintenance or component replacements.

Troubleshooting Common Issues 🔍

Electric bike engine systems can experience various operational issues that require systematic troubleshooting approaches. Understanding common problems and their solutions enables quick resolution and minimizes downtime.

Power Output Reduction

Reduced power output typically indicates battery degradation, controller issues, or mechanical problems. Begin troubleshooting by checking battery voltage under load and comparing to manufacturer specifications. Low voltage indicates battery replacement needs or charging system problems.

Inspect all electrical connections for corrosion or looseness that creates resistance and reduces power transfer. Clean connections and apply appropriate contact treatments to restore full electrical conductivity. Additionally, verify proper controller programming and sensor calibration.

Unusual Noise or Vibration

Mechanical noise from electric bike engines usually indicates bearing wear, misalignment, or foreign object interference. Remove the motor cover and inspect internal components for damage or debris. Replace worn bearings and ensure proper lubrication of all moving parts.

Electrical noise may indicate controller problems or electromagnetic interference from nearby devices. Use oscilloscope testing to identify electrical noise sources and implement appropriate filtering or shielding solutions.

Range Reduction

Decreased riding range typically results from battery degradation, increased system resistance, or changed riding patterns. Conduct systematic range testing under controlled conditions to isolate variables and identify root causes.

Inspect tire pressure, drivetrain lubrication, and wheel alignment for mechanical factors that increase energy consumption. Additionally, verify proper controller programming and sensor operation that affects power management efficiency.

Comparative Analysis

Choosing the optimal electric bike engine requires careful comparison of available technologies, performance characteristics, and cost considerations. This analysis provides objective criteria for evaluation and selection.

Mid-Drive vs Hub Motor Comparison 🎯

Mid-drive electric bike engines offer several advantages over hub motor systems, particularly for demanding applications. The central motor position provides optimal weight distribution and lower center of gravity, improving handling and stability. Additionally, mid-drive systems leverage the bicycle’s existing gears, providing mechanical advantage for climbing and efficiency optimization.

Hub motor electric bike engines excel in simplicity and installation ease. The self-contained design requires minimal bicycle modifications and typically costs less than equivalent mid-drive systems. Furthermore, hub motors provide immediate power delivery without drivetrain wear concerns.

Performance differences become apparent in challenging terrain and extended riding conditions. Mid-drive systems maintain efficiency across various speeds and terrain types, while hub motors may experience reduced efficiency at low speeds or steep grades. However, hub motors offer quiet operation and require less maintenance than mid-drive systems.

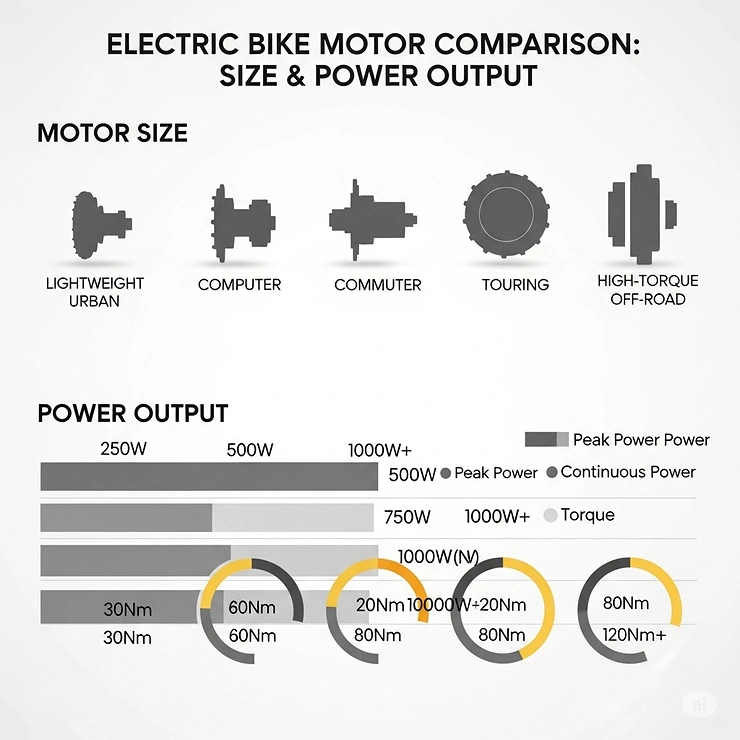

Power Output Considerations ⚡

Electric bike engine power ratings require careful interpretation beyond simple wattage specifications. Continuous power rating indicates sustained output capability, while peak power describes maximum short-term output for acceleration or climbing. These distinctions significantly impact real-world performance and suitability for specific applications.

500W electric bike engines provide adequate power for flat terrain commuting and recreational riding. These motors excel in efficiency and regulatory compliance while offering good range and modest purchase costs. However, 500W systems may struggle with steep climbs or heavy cargo loads.

750W electric bike engines represent the optimal balance for most riders, providing sufficient power for challenging terrain while maintaining reasonable efficiency and legal compliance in many jurisdictions. These motors handle hills confidently and accommodate heavier riders or cargo loads.

1000W+ electric bike engines deliver maximum performance for demanding applications including cargo hauling, steep terrain, or high-speed riding. However, these powerful motors consume more battery power, require robust cooling systems, and may exceed legal limits in some areas.

Efficiency and Range Analysis 📊

Electric bike engine efficiency directly impacts riding range and operating costs. Efficiency varies significantly between motor types, operating conditions, and system configurations. Understanding these factors enables realistic range expectations and optimal system selection.

Motor efficiency typically peaks at moderate power outputs and decreases at very low or very high power levels. This characteristic means that electric bike engines perform most efficiently during steady cruising rather than frequent acceleration or maximum power climbing.

System-level efficiency includes motor, controller, and battery efficiency combined. High-quality systems achieve 80-85% overall efficiency, while budget systems may operate at 70-75% efficiency. This 10-15% difference significantly impacts range and performance.

Environmental factors including temperature, humidity, and altitude affect electric bike engine efficiency and range. Cold temperatures reduce battery capacity and increase motor resistance, while high altitudes reduce air density and cooling effectiveness.

Cost-Benefit Analysis 💰

Electric bike engine systems require significant initial investment but provide long-term value through reduced transportation costs and improved mobility. Analyzing total cost of ownership includes purchase price, installation costs, maintenance expenses, and operational savings.

Conversion kits typically cost $300-$800 depending on power level and quality, while complete e-bike systems range from $1,500-$5,000+. Professional installation adds $100-$300 for conversion kits, while complete bikes arrive ready to ride.

Operating costs include electricity for charging, maintenance supplies, and periodic component replacements. Electricity costs average $0.10-$0.20 per 100 miles depending on local rates and system efficiency. Maintenance costs vary with usage and system quality but typically average $100-$200 annually.

Transportation cost savings depend on replaced vehicle usage but often exceed $1,000 annually for regular commuters. Reduced fuel costs, parking fees, and vehicle maintenance provide substantial savings that offset electric bike engine system costs within 2-3 years.

Quality and Reliability Metrics 🏆

Electric bike engine reliability varies significantly between manufacturers and price points. Quality indicators include component specifications, manufacturing standards, warranty coverage, and customer support availability.

Premium manufacturers like BAFANG invest heavily in research and development, resulting in superior performance and reliability. These companies typically offer 2-3 year warranties and global service networks that ensure long-term support availability.

Budget electric bike engine systems may offer adequate performance for light-duty applications but often lack durability for demanding use. Component quality varies widely, and warranty coverage may be limited or difficult to obtain.

User reviews and independent testing provide valuable reliability insights beyond manufacturer specifications. Look for patterns in customer feedback regarding longevity, support quality, and common failure modes when evaluating different systems.

Case Studies and Success Stories

Real-world implementations of electric bike engine technology demonstrate practical benefits and applications across diverse user scenarios. These case studies provide insights into optimal system selection and configuration strategies.

Urban Commuter Success Story 🏙️

Sarah Chen, a marketing professional in San Francisco, transformed her daily commute with a BAFANG Mid Drive Kit installation on her existing road bike. Previously spending $300 monthly on parking and $150 on public transportation, Sarah’s electric bike engine conversion eliminated these costs while improving her commute experience.

The 750W mid-drive electric bike engine enables Sarah to maintain 20-25 mph speeds on San Francisco’s challenging hills while arriving at work fresh and professional. Her 12-mile roundtrip commute takes 35 minutes compared to 50 minutes by car in traffic, providing additional time savings.

Over 18 months of use, Sarah reports 98% reliability with only routine maintenance required. Her total investment of $1,200 (including professional installation) paid for itself in 8 months through eliminated transportation costs. Additionally, Sarah lost 15 pounds and significantly improved her cardiovascular fitness through regular cycling.

Key Success Factors:

- Proper motor sizing for terrain demands

- Professional installation ensuring reliability

- Integration with existing quality bicycle

- Realistic expectations and proper maintenance

Cargo Delivery Implementation 📦

Green Delivery Solutions, a local courier service, equipped their fleet with Voilamart 1000W hub motor conversions to reduce operational costs and environmental impact. The company converted 20 cargo bikes with custom modifications for delivery box mounting and enhanced braking systems.

Each electric bike engine conversion costs $800 including installation and modifications. Operating costs average $0.15 per mile compared to $0.45 per mile for motorcycle delivery. Additionally, the e-bikes access bike lanes and pedestrian areas restricted to motor vehicles, reducing delivery times significantly.

Driver satisfaction increased dramatically with electric bike engines eliminating physical strain from long delivery routes. Employee retention improved 40% after e-bike implementation, reducing training costs and maintaining experienced delivery staff.

Measured Results:

- 67% reduction in per-mile operating costs

- 25% faster delivery times in urban areas

- 40% improvement in driver retention

- Zero emissions for enhanced environmental compliance

Rural Property Management Application 🌾

Tom Martinez manages a 500-acre ranch in Colorado and utilizes a BAFANG 1000W mid-drive electric bike engine for daily property inspection and livestock monitoring. The powerful motor handles steep terrain and heavy gates while providing quiet operation that doesn’t disturb animals.

The electric bike engine system replaced ATV usage for most ranch tasks, reducing fuel costs and environmental impact. Tom’s daily property rounds cover 15-20 miles across challenging terrain, previously requiring multiple ATV trips with fuel stops.

Equipment carrying capacity improved with custom cargo attachments designed for fence repair tools, veterinary supplies, and livestock feed. The electric bike engine provides sufficient power for these loads while maintaining maneuverability in tight spaces.

Operational Benefits:

- 80% reduction in fuel consumption

- Quieter operation improving animal welfare

- Enhanced maneuverability in confined spaces

- Lower maintenance costs compared to ATV

Recreational Adventure Enhancement 🏔️

The Mountain View Cycling Club equipped their guided tour fleet with ENGWE Engine Pro complete e-bike systems to accommodate riders of varying fitness levels. The 1000W electric bike engines enable challenging mountain tours previously accessible only to experienced cyclists.

Tour capacity increased 150% as the electric bike engines allowed less experienced riders to complete demanding routes. Customer satisfaction scores improved significantly with participants rating tours higher when electric assistance was available.

The folding design facilitates transportation to remote trailheads using standard vehicles rather than specialized bike trailers. This capability expanded tour offerings to previously inaccessible locations, differentiating the club’s services in a competitive market.

Business Impact:

- 150% increase in tour participation

- Higher customer satisfaction ratings

- Access to previously inaccessible locations

- Reduced transportation equipment requirements

Accessibility Success Implementation ♿

The adaptive cycling program at Regional Medical Center utilizes specialized BAFANG hub motor systems to provide cycling opportunities for mobility-impaired individuals. The electric bike engines compensate for reduced physical capability while providing therapeutic exercise benefits.

Participants with partial paralysis, joint limitations, or cardiovascular restrictions benefit from electric bike engine assistance that enables cycling participation. The program serves 150+ individuals weekly with demonstrable health improvements documented through medical monitoring.

Custom mounting systems accommodate various adaptive equipment including hand controls, specialized seating, and stability aids. The electric bike engines provide adequate power for these modifications while maintaining safe operation characteristics.

Health Outcomes:

- 30% improvement in cardiovascular markers

- Enhanced mobility and independence

- Reduced depression and anxiety scores

- Increased social interaction and engagement

Future Trends and Market Evolution

Electric bike engine technology continues evolving rapidly with innovations in motor design, control systems, and integration capabilities. Understanding these trends helps predict future developments and optimal investment timing.

Emerging Motor Technologies 🔬

Next-generation electric bike engines incorporate advanced materials including carbon fiber housings, ceramic bearings, and rare earth magnet optimization. These improvements reduce weight while increasing power density and efficiency. Additionally, manufacturing techniques like 3D printing enable complex geometries impossible with traditional methods.

Integrated cooling systems become standard features as power densities increase. Active cooling using small pumps and heat exchangers maintains optimal operating temperatures during sustained high-power operation. These systems prevent thermal derating that reduces performance during challenging conditions.

Wireless power transfer technology may eliminate charging cables and enable charging while riding. Inductive charging systems embedded in roadways or parking areas could provide seamless power replenishment for electric bike engines during regular use.

Smart System Integration 📱

Artificial intelligence integration enables predictive maintenance and optimized performance tuning. Electric bike engine systems monitor operating parameters continuously and predict component wear, failure modes, and optimal maintenance timing. This capability reduces unexpected breakdowns and maintenance costs.

Smartphone integration provides comprehensive system monitoring and control capabilities. Riders access detailed performance data, customize motor behavior, and receive maintenance notifications through dedicated applications. Additionally, GPS integration enables route optimization based on battery capacity and terrain analysis.

Vehicle-to-everything (V2X) communication allows electric bike engines to interact with traffic systems, other vehicles, and infrastructure. This connectivity improves safety through collision avoidance and provides traffic optimization benefits for urban transportation systems.

Sustainability and Environmental Impact 🌱

Manufacturing sustainability becomes increasingly important as electric bike engine production scales. Companies invest in renewable energy production, recycling programs, and reduced material consumption. Additionally, lifecycle analysis drives design decisions that minimize environmental impact.

Battery recycling programs address end-of-life concerns for electric bike engine systems. Advanced recycling techniques recover valuable materials including lithium, cobalt, and rare earth elements for reuse in new production. These programs reduce mining requirements and environmental impact.

Carbon footprint analysis demonstrates significant environmental benefits from electric bike engine adoption. Lifecycle emissions including manufacturing, operation, and disposal remain substantially lower than equivalent motor vehicle transportation.

Market Expansion and Accessibility 💡

Electric bike engine costs continue declining as production volumes increase and manufacturing efficiency improves. Technology trickle-down from premium systems brings advanced features to budget-friendly options, improving accessibility for broader populations.

Financing options and subscription services make electric bike engines more accessible to cost-conscious consumers. Leasing programs and pay-per-use models reduce initial investment barriers while providing upgrade flexibility as technology evolves.

Global market expansion drives standardization efforts that improve compatibility and reduce costs. Common mounting interfaces, electrical standards, and communication protocols enable component interchangeability and competitive pricing.

Regulatory Evolution and Standardization ⚖️

Safety standards continue evolving with increased electric bike engine adoption. Enhanced testing requirements and certification processes ensure product safety and reliability. Additionally, international harmonization reduces compliance costs and improves global market access.

Power and speed regulations adapt to technology capabilities and urban transportation needs. Some jurisdictions consider higher power limits for specific applications including cargo delivery and accessibility adaptations. These changes expand electric bike engine application possibilities.

Insurance and liability frameworks develop to address electric bike engine risks and benefits. Specialized coverage options provide appropriate protection while recognizing reduced risk profiles compared to motor vehicles.

Investment and Purchase Decision Framework

Selecting optimal electric bike engine systems requires systematic evaluation of technical requirements, financial considerations, and long-term objectives. This framework provides structured decision-making tools for various user scenarios.

Requirements Analysis Matrix 📋

Begin electric bike engine selection by defining specific requirements across multiple categories. Performance requirements include power needs, range expectations, terrain challenges, and speed requirements. These factors determine minimum motor specifications and system configurations.

Usage pattern analysis identifies duty cycle requirements, environmental conditions, and loading scenarios. Daily commuters require different capabilities than weekend recreational riders or commercial delivery applications. Furthermore, climate conditions affect system selection and configuration needs.

Integration requirements assess existing bicycle compatibility, modification tolerance, and maintenance capability. Some electric bike engine systems require extensive modifications while others install with minimal changes. Additionally, technical skill levels affect installation feasibility and ongoing maintenance requirements.

Financial Planning and Budgeting 💰

Electric bike engine investments require comprehensive cost analysis including initial purchase, installation, accessories, and ongoing operational expenses. Budget allocation should include contingency funds for unexpected modifications or upgrades necessary for optimal performance.

Financing options including manufacturer programs, credit alternatives, and leasing arrangements may improve affordability and cash flow management. Compare total costs across different financing scenarios to identify optimal approaches for individual financial situations.

Return on investment calculations consider transportation cost savings, health benefits, and lifestyle improvements. Quantifiable savings include fuel, parking, public transportation, and vehicle maintenance costs displaced by electric bike engine usage.

Vendor Evaluation Criteria 🏭

Electric bike engine manufacturer evaluation requires assessment of technical capabilities, quality standards, support infrastructure, and financial stability. Established companies with proven track records provide greater assurance of long-term support and parts availability.

Warranty coverage and support quality significantly impact long-term ownership costs and satisfaction. Compare warranty terms, service network availability, and customer support responsiveness across different manufacturers and products.

Product roadmap and upgrade compatibility ensure continued value as technology evolves. Some electric bike engine systems support firmware updates and component upgrades while others require complete replacement for technology advancement.

Implementation Strategy Development 📈

Successful electric bike engine implementation requires phased approaches that minimize risk and optimize outcomes. Initial system selection should slightly exceed minimum requirements to provide growth capacity and unexpected demand handling.

Installation planning includes professional service evaluation, timeline coordination, and backup transportation arrangements. Professional installation ensures optimal performance and warranty compliance while reducing risk of damage or improper configuration.

Training and familiarization programs help users maximize system capabilities and identify potential issues early. Understanding proper operation, maintenance requirements, and troubleshooting procedures prevents problems and extends system life.

Success Measurement and Optimization 📊

Establish baseline measurements before electric bike engine installation to enable accurate performance assessment. Key metrics include transportation costs, travel times, physical fitness indicators, and satisfaction levels across relevant categories.

Regular performance monitoring identifies optimization opportunities and potential issues requiring attention. Document range performance, charging patterns, and maintenance requirements to establish operational patterns and identify deviations.

Continuous improvement processes adapt system configuration and usage patterns based on experience and changing requirements. Many electric bike engine systems offer programmable parameters that enable fine-tuning for optimal performance and efficiency.

Frequently Asked Questions

❓ How fast can an electric bike engine go?

❓ What's the average lifespan of an electric bike engine?

❓ Can I install an electric bike engine myself?

❓ How much does electric bike engine maintenance cost annually?

❓ What's the difference between 500W and 750W electric bike engines?

Ultimate Electric Bike Engine Selection Guide! 🎯

→Transform your cycling experience with these proven electric bike engine systems. Click any highlighted motor to discover current pricing and customer reviews. Your perfect e-bike upgrade awaits! ⚡🚴♂️

Conclusion

Electric bike engines represent transformative technology that democratizes cycling for riders of all ages and abilities. From budget-friendly conversion kits starting around $200 to premium integrated systems exceeding $3,000, options exist for every application and budget.

The seven electric bike engines featured in this guide offer proven performance across diverse riding scenarios. Voilamart’s 1000W conversion kit provides exceptional value for budget-conscious builders, while BAFANG’s mid-drive systems deliver professional-grade performance and reliability. Meanwhile, innovative solutions like the Bimotal Elevate point toward exciting future possibilities in electric bike engine design.

Success with electric bike engines depends on careful system selection matching your specific requirements, proper installation and configuration, and consistent maintenance practices. Moreover, understanding your local regulations ensures legal compliance while maximizing system capabilities.

The electric bike engine market continues evolving rapidly with improvements in efficiency, integration, and affordability. Today’s investment in quality electric bike engine technology provides years of enhanced mobility, reduced transportation costs, and improved health benefits.

Whether you’re commuting to work, exploring mountain trails, or simply enjoying leisurely rides, the right electric bike engine transforms ordinary bicycles into extraordinary transportation solutions. The time has never been better to join the electric cycling revolution! 🚴♂️⚡

Ready to Electrify Your Ride? 🔥

→Don’t wait another day to experience the freedom and joy of electric cycling. Click any highlighted electric bike engine to start your transformation journey today! Your future self will thank you for taking action now! 🎯

Recommended for You:

- 7 Best 750 Watt Ebike Models That Will Transform Your Commute in 2025

- 7 Best Mini Electric Bike Models That Will Transform Your 2025 Commute

- 7 Best Electric Bike Looks Like Motorcycle Models That Turn Heads in 2025

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗